A brief history of superchargers (this is a long story)

Those great big whine-boxes you see on top of drag engines and poking through the bonnets of various old muscle cars and hot rods have a few names: supercharger or blower being the most common. Basically they are an air pump that sucks in normal air, uses two rotors to compress it, and then it is jammed into the motor to make beautiful clouds of tyre smoke.

Using compressed air to make things better, as a basic concept, has been around for a couple of centuries, and the concept of a twin-rotor air pump has been around since Francis Marion Roots patented the design in 1860. When it comes to ramming compressed air into engines using spinning rotors powered by the crankshaft, many racing cars of the pre-World War 2 era used this technology including those by Mercedes, Alfa-Romeo, Bugatti, Bentley, Sunbeam, Miller, and Fiat. However, Mercedes pioneered the concept of supercharged road cars in 1921.

Once WW2 was over a hot rodder called Barney Navarro (that's him pictured in the hot rod, below) was credited as the first bloke to grab a supercharger and fit it to his V8 as a way of improving engine performance, way back around 1948-49. In these days the Pre-War Ford "flathead" V8 was the king of the scene, and the hottest way to soup them up was the Italmecanicca "S.C.o.T" supercharger (pictured under Barney), which was an Italian-made Roots-style supercharger designed for little European motors but that suited the smaller-capacity Flathead engine.

While there were all sorts of superchargers available in those post-War years, the most popular option (partly due to their bargain basement price) were the diesel blowers found on big 71-series Detroit Diesel in-line truck motors.

The GM blowers are often referred to by numbers like 4/71 and 6/71, which refers to the size of two-stroke diesel engine the pump had been fitted to. For example, a 6/71 was an inline six-cylinder where each cylinder displaced 71ci, for a total of 426ci.

The in-line engines were the go-to for hot rodders and racers because the pump bolted flat to the side of the engine and that made it a much simpler task to fabricate an intake manifold upon which to mount your glorious new boost-maker.

These old school Roots superchargers use two- or three-lobe rotors to compress the air, but they were originally never envisaged as a way of adding horsepower. On diesel engines these are used as scavenge pumps!

The below image shows a three-rotor set-up, which has had the case machined for better clearance to the rotor tips. This is important as the supercharger can't compress the air if there is too much gap between the rotors, or between the case and the rotor tip.

Because they weren't intended for adding horsepower to petrol motors there are a few drawbacks: one is the rotors need a lot of upkeep to ensure they fit closely to the walls of the case and adequately compress the air, and second is they heat the air being fed into the motor massively, which can heat soak the engine.

In old-style engines fuel was added above the superchargers, either by carburettors or by mechanical injection, as a way of keeping the rotors cool and also cooling the compressed charge air. Turning those rotors also sapped power from the crankshaft, which is why people bolting big blowers onto very tired engines often lose power!

Here you can see how the rotors suck the air in from the carburettors or injection hat above, and then pass it out the bottom in its now-boosted form.

As the money flowed into drag racing in the 1960s and '70s, the aftermarket started developing their own superchargers and race-spec parts like Teflon-coated rotors, lighter housings, special intake manifolds and more. By the late 1970s Top Fuel dragsters - the fastest accelerating land vehicles on Planet Earth - were running new 8/71 superchargers made entirely as an aftermarket part.

These bigger superchargers suited the mega-cubic-inch V8s that had been born from racing in the late 1960s, and today you can buy a plethora of aftermarket superchargers that are even bigger again. Many "big-block" (or +400ci) old school V8s run 8/71s if they are a "street" engine, while 10/71s and even 14/71s are used on alcohol-fulled drag engines.

An evolution of the Roots-style positive displacement supercharger is the "twin-screw" supercharger, also known as Lysholm superchargers. These differ from Roots blowers as Lysholms have a male and female screw rotor with different blade counts to compress the air.

While "screw" superchargers are claimed to offer finer tolerances between rotors compared to traditional Roots blowers, engineers will debate which method of squashing air is best for a given engine, and this is really the crux of which type of supercharger is better: it all comes down to the engine you're fitting the blower to!

Centrifugal or "side-mount" superchargers were first thought-up in the late 1800s, and first gained significant use during World War II on aircraft. These units look like a belt-driven turbocharger, but offer benefits the positive displacement superchargers cannot.

In the 1950s Ford, Packard, Kaiser and Studebaker all offered centrifugal supercharger options on factory production models, supplied by McCulloch and Paxton, who were both companies run by Robert Paxton McCulloch. These supercharged models found success in racing but the maintenance and upkeep on road cars limited their appeal among non-enthusiasts.

Centrifugal superchargers found huge popularity in the 1990s as they were easier to fit under the bonnet of many street cars and didn't require much of the intense work to engine hardware a Roots supercharger did to fit. While they tend to not make full boost until at the engine's redline, this suits race-style engines that are only designed to run in the powerband.

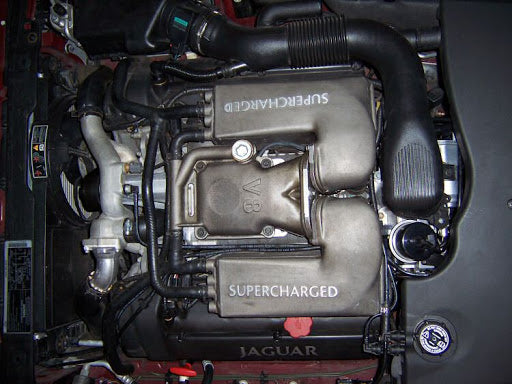

Beginning in 1985, Eaton's TVS-series superchargers set out to refine the engineering underpinning the Roots blower, with advancements in bearing technology, metallurgy used in the rotors and cases, as well as manufacturing techniques and design processes. Their M-series superchargers found use in many OE manufacturer set-ups including high-performance Ford Mustangs, Thunderbirds, and pick-up trucks, as well as on GM 3.8-litre V6s, plus exotic Jaguars and Aston Martins.

Superchargers really kicked into overdrive with the introduction of Eaton TVS-style units on General Motors' high-performance Gen IV V8s, including the 580hp 6.2-litre LSA (5th-gen Camaro ZL1, HSV GTS and Clubsport, and Cadillac CTS-V), as well as the 650hp 6.2-litre hand-built LS9 (C6 Corvette ZR1 and HSV GTS-R W1). Huge power was suddenly available as a crate motor with a factory warranty, Eaton having cured many of the issues engineers had with traditional Roots superchargers.

Eaton worked with aftermarket suppliers, like Australia's Harrop Engineering, to package their four-lobe rotor set-ups into new housings to suit a range of OE and aftermarket fitments, including the huge new 2.65-litre TVS2650 seen below on a built-LS V8. With four-digit power figures capable from these superchargers without the heat-soak and fuel mixing issues found with old school superchargers, many people wanting a fast street car suddenly had a very attractive way of turning their tyres into big, smokey clouds.

This basically takes us up to the current day, though many of these companies continue to develop their packages to reduce parasitic loss from superchargers, reduce intake charge heat, and provide higher headroom for more power. Many modern hot rodders are now spoiled for choice when it comes to options for boosting their street car's performance.